Classic car restoration is indeed challenging. Finding accessories of vintage vehicle is not easy because they are obsolete and discontinued by the manufacturers and suppliers. Despite widespread online stores, some classic car parts can be incredibly difficult to track down. Even if you do succeed in finding the part, often it will be extremely old or over-used, or sometime misfit.

In this scenario, 3D printing is a special boon for classic car owners and curators. Its technology allows you to reincarnate a brand new part to your exact specifications.

Of course, certain auto parts that require safety measures or heavy-weight cannot be 3D printed at small scale (like engine, pistons, brake system, blocks or wheel bearings).

However, 3D printing is ideal for recreating those smaller accessories such as door handles, wing mirror covers, dashboard panels, speedo meter frame, needles, knobs, dash pieces, cup holders, frames of front and back lights, fan wings, and hood ornaments.

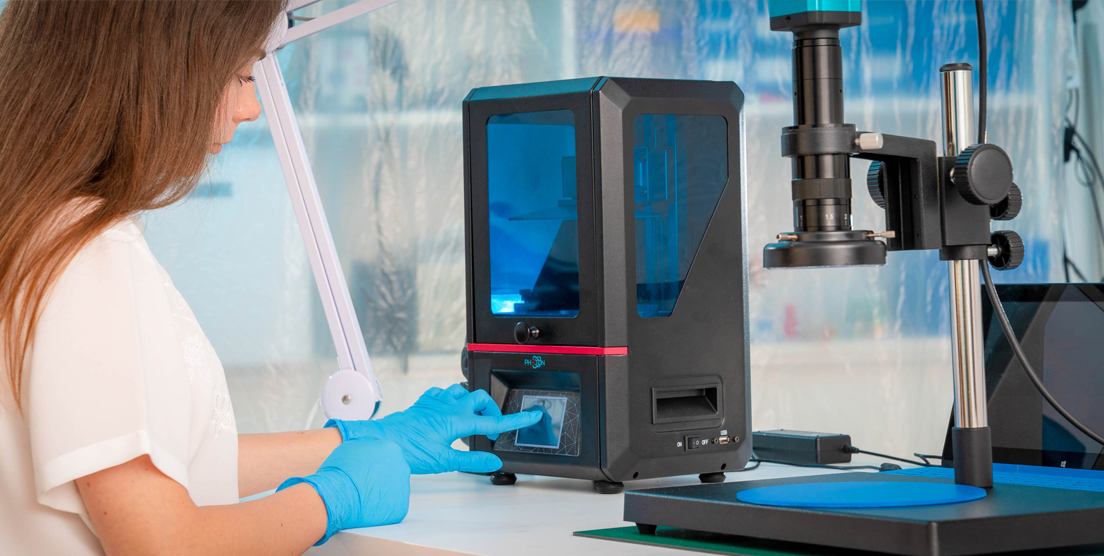

The 3D printing hinges upon modern manufacturing technologies that build parts layer-by-layer. This is why, it is also called Additive Manufacturing (AM) technique. Some of well-known technologies are as follows.

- Stereolithography (SLA)

- Selective Laser Sintering (SLS)

- Fused Deposition Modeling (FDM)

- Digital Light Process (DLP)

- Multi Jet Fusion (MJF)

- PolyJet

- Direct Metal Laser Sintering (DMLS)

- Electron Beam Melting (EBM)

Here each technology differs from other in the way or other. In addition, the choice of raw material, surface finish, durability, and manufacturing speed and cost also varies.